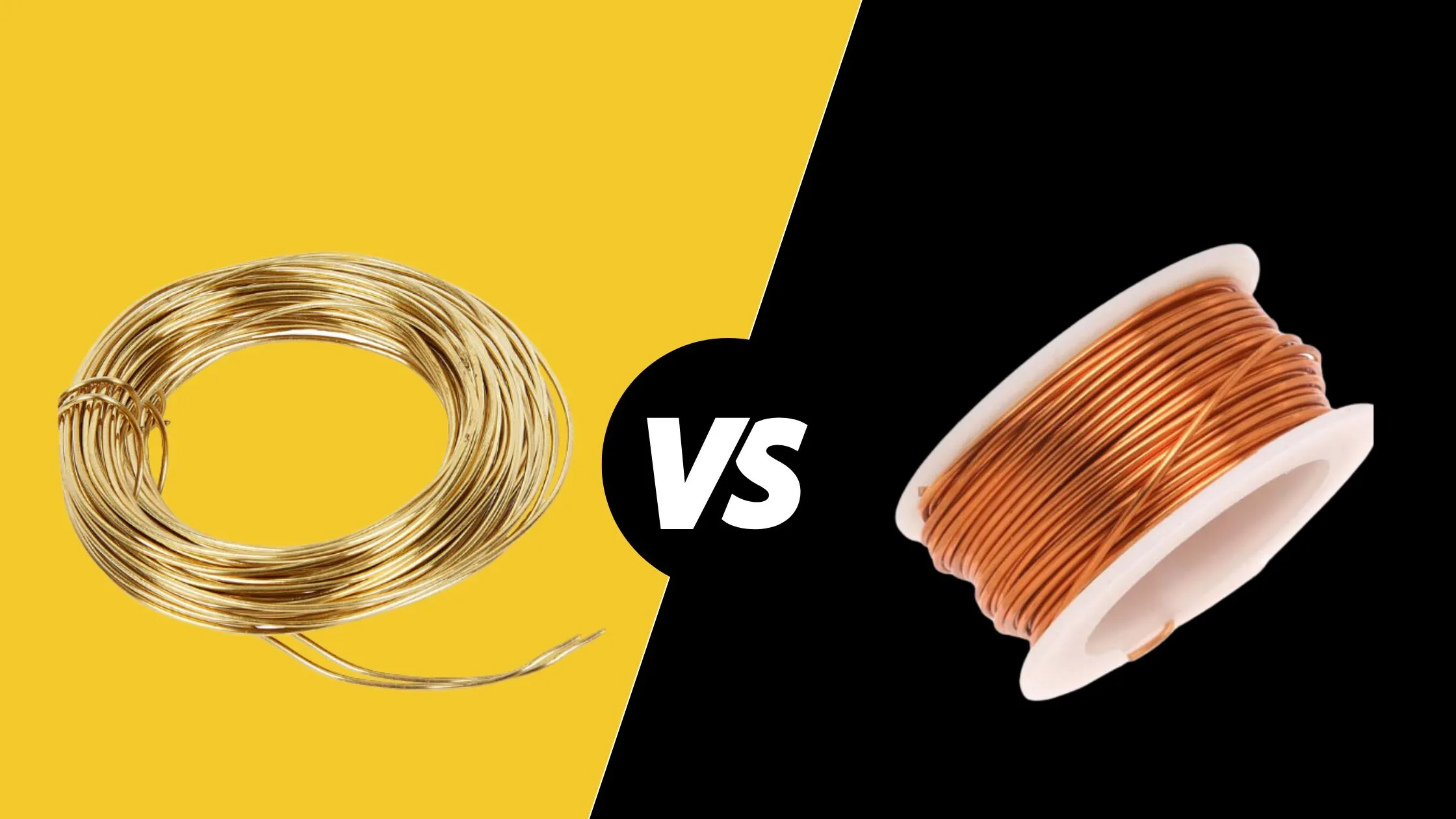

Have you ever wondered about the difference between brass vs copper? These two versatile metals have been used for centuries in a wide range of products and applications, each with its own unique set of properties and characteristics. In this informative blog post, we will explore the distinct differences between brass and copper, their individual applications, and the best uses for each. Whether you’re a DIY enthusiast, a hobbyist, or a professional in the manufacturing industry, understanding the nuances of these two metals can help you make informed decisions when it comes to selecting the right material for your project. So, let’s delve into the world of brass and copper and gain a deeper understanding of their practical applications and capabilities.

Historical Context and Properties

One of the earliest alloys known to man, brass has been used for thousands of years due to its favorable properties. Copper, on the other hand, has a rich historical significance as one of the first metals to be utilized by humans.

Historical Use of Brass

One of the earliest recorded uses of brass dates back to ancient Egypt and Mesopotamia, where it was used for various purposes such as decorative objects, coins, and tools. The Roman Empire also extensively used brass for statues, coins, and military equipment due to its durability and aesthetic appeal.

Historical Use of Copper

Copper has a long and storied history, with evidence of its use dating back to around 10,000 years ago in the Middle East. It was the first metal to be smelted from its ore, and its malleability made it an essential material for making tools, jewelry, and weapons in ancient civilizations such as the Indus Valley and Mesoamerica.

With the advent of metallurgy, copper became a vital metal in the Bronze Age, where it was alloyed with tin to create the eponymous bronze. This allowed for the creation of stronger and more durable tools and weapons.

Physical Properties of Brass and Copper

Historically, brass was prized for its corrosion resistance, malleability, and acoustic properties, making it the preferred material for musical instruments, decorative items, and coinage. On the other hand, copper’s excellent conductivity, ductility, and heat resistance have made it indispensable in electrical wiring, plumbing, and heat exchangers.

Copper, being a highly conductive metal, is used in electrical wiring, plumbing, and heat exchangers. Its excellent ductility and heat resistance make it a vital material in a variety of applications, from industrial machinery to consumer electronics.

Comparing brass vs copper

Unlike other metals, Brass and Copper are often confused due to their similar appearance. However, they have distinct differences in composition, properties, and applications. Let’s examine the key differences between Brass and Copper in the table below:

| Brass | Copper |

|---|---|

| Alloy of copper and zinc | Pure elemental metal |

| Varied compositions for different properties | Naturally soft and malleable |

| Good corrosion resistance | Excellent electrical conductivity and thermal conductivity |

| Yellow-gold appearance | Red-orange appearance |

Composition and Alloy Characteristics

Any discussion on Brass vs Copper must begin with their composition and alloy characteristics. Brass is an alloy of copper and zinc, while Copper is a pure elemental metal. Brass can have varied compositions to achieve different properties, while Copper is naturally soft and malleable.

Corrosion Resistance and Durability

One of the key differences between Brass and Copper lies in their corrosion resistance and durability. Copper has excellent electrical conductivity and thermal conductivity, making it ideal for electrical wiring and plumbing applications. On the other hand, Brass offers good corrosion resistance and is often used for decorative and architectural applications.

Copper, being a noble metal, is resistant to corrosion and has high durability in various environments, making it a preferred choice for outdoor and industrial applications.

Thermal and Electrical Conductivity

The thermal and electrical conductivity of Brass and Copper sets them apart in terms of their applications. The pure elemental nature of Copper gives it excellent electrical conductivity and thermal conductivity, making it perfect for electrical wiring and heat exchange applications. On the other hand, Brass offers relatively lower electrical and thermal conductivity, making it a suitable choice for decorative and architectural applications.

Malleability and Workability

Comparing the malleability and workability of Brass and Copper reveals their suitability for different manufacturing processes. Malleability and workability are the key attributes of Copper, making it an ideal choice for forming into different shapes and structures. Brass, while still malleable, is comparatively less workable than Copper due to its alloy nature.

Applications in Various Industries

Now let’s take a closer look at the applications of brass and copper in various industries.

Brass Applications

To understand the wide range of applications of brass, one must look no further than the automotive industry, where brass is used in the manufacturing of radiators, air conditioning units, and various other components. In the construction industry, brass finds its use in the form of pipes and fittings, thanks to its corrosion resistance and malleability, making it an ideal material for plumbing systems. Additionally, in the production of musical instruments, brass is valued for its acoustic properties, leading to the creation of horns, trumpets, and other instruments.

Furthermore, in the world of interior design and décor, brass is often used in the form of doorknobs, handles, and decorative fixtures due to its aesthetic appeal. It is also utilized in the creation of jewelry and coinage, owing to its attractive golden hue.

Copper Applications

To discuss the applications of copper, one must note its extensive use in electrical wiring and telecommunications, where its high electrical conductivity and durability make it an essential component. In the construction industry, copper is utilized in roofing, gutters, and downspouts due to its corrosion resistance and longevity. Moreover, in the realm of industrial machinery and equipment, copper is employed in various forms, such as heat exchangers and condensers, thanks to its excellent thermal conductivity.

It is also important to recognize the medical industry’s reliance on copper for its antimicrobial properties, with copper alloys being utilized in the production of surfaces, equipment, and tools to reduce the spread of infections in healthcare settings, a particularly pertinent point in light of recent events.

Considerations for Material Choice

Despite their similarities, brass and copper have unique qualities that make them suitable for different applications. When deciding between the two materials, several factors should be considered to ensure the right choice for your specific needs.

Cost-Effectiveness and Availability

Material cost and availability can significantly impact the decision between brass and copper. While brass is generally less expensive due to its combination of copper and zinc, copper is known for its superior conductivity and corrosion resistance. It is essential to consider the availability of the material and its impact on the overall cost, especially for larger-scale manufacturing and construction projects.

Environmental Impact and Sustainability

Availability and environmental impact play a significant role in the selection of materials for various applications. Copper is a highly sustainable material as it can be recycled repeatedly without losing its essential properties. In contrast, brass, which contains a mixture of copper and zinc, may pose challenges in terms of recycling due to the blending of materials. When considering the environmental impact, it is crucial to assess the potential for recycling and the overall sustainability of the chosen material.

Environmental considerations such as recycling and sustainability should not be overlooked when choosing between brass and copper for manufacturing or construction projects. It is essential to prioritize materials that have a minimal environmental impact and can be recycled to promote sustainability in the long term.

Future Trends in Material Usage

On a broader scale, advancements in material science and technology are driving the future trends in the utilization of brass and copper. As industries continue to prioritize sustainability and cost-effectiveness, there is a growing demand for innovative materials that strike a balance between performance and environmental impact. Material selection will increasingly focus on factors such as recyclability and availability to meet the evolving needs of industries and consumers.

Material advancements and sustainability will influence the future trends in the usage of brass and copper. As industries adapt to changing environmental regulations and consumer demands, the development of eco-friendly and cost-effective materials will continue to shape the landscape of material usage across various sectors.

The Conclusion

The differences and applications of brass and copper have been clearly outlined, allowing for a better understanding of the two materials. While both are alloys of copper, brass’s addition of zinc gives it unique properties such as corrosion resistance and malleability, making it suitable for applications such as plumbing fittings and musical instruments. On the other hand, copper’s excellent electrical conductivity and heat resistance make it ideal for electrical wiring and heat exchangers. Understanding the distinctions between these two versatile materials is essential in selecting the right one for specific applications, ultimately leading to more efficient and effective use of each material.